Enquiry List () (0)

- 31 Oct 2024

Ensuring Safety in Freezing Climates: Hughes' Frost Protected Safety Shower Options

When the temperatures drop with the winter months most site managers won’t consider the effect on their emergency showers. Yet, in frigid environments where safety is paramount, the condition of your safety equipment shouldn’t be an afterthought—it's a lifesaver. From remote oil rigs to rapidly changing construction sites, functioning safety equipment can be the difference between minor and life-threatening injury.

When temperatures drop below 0°C (32°F), water inside pipes can begin to freeze. In these circumstances, the best scenario is that the unit is inoperable, presenting a further danger in an emergency. However, as water freezes, it expands, putting pressure on the pipe walls from the inside. This expansion can cause pipes to split or burst if the pressure becomes too great, requiring costly repairs.

To mitigate these risks and ensure a comfortable water temperature for the user Hughes have developed several safety shower solutions for rapid decontamination on colder sites with concerns of the pipework freezing.

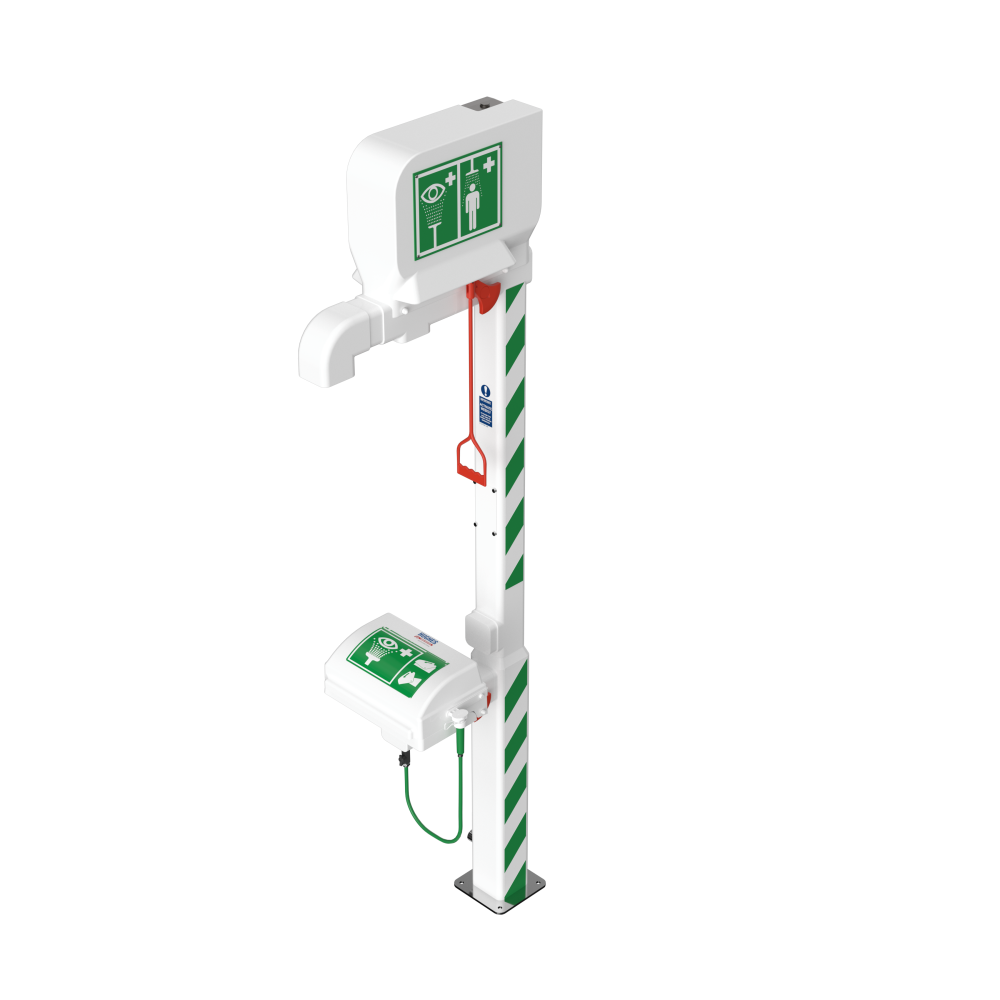

Heated safety showers are developed for work sites with a water source that are situated outdoors, facing harsh ambient temperatures which pose a risk to the pipework. The type of heated unit necessary for your worksite will depend on the harshness of the ambient climate.

Trace-tape heated safety showers work by insulating and heating the pipework to protect against frost. This type of unit is most appropriate where temperatures see lows of -25C.

For even harsher conditions reaching as low as -35C immersion heated units such as the STD-MH-5KS/11KS are the more appropriate solution.

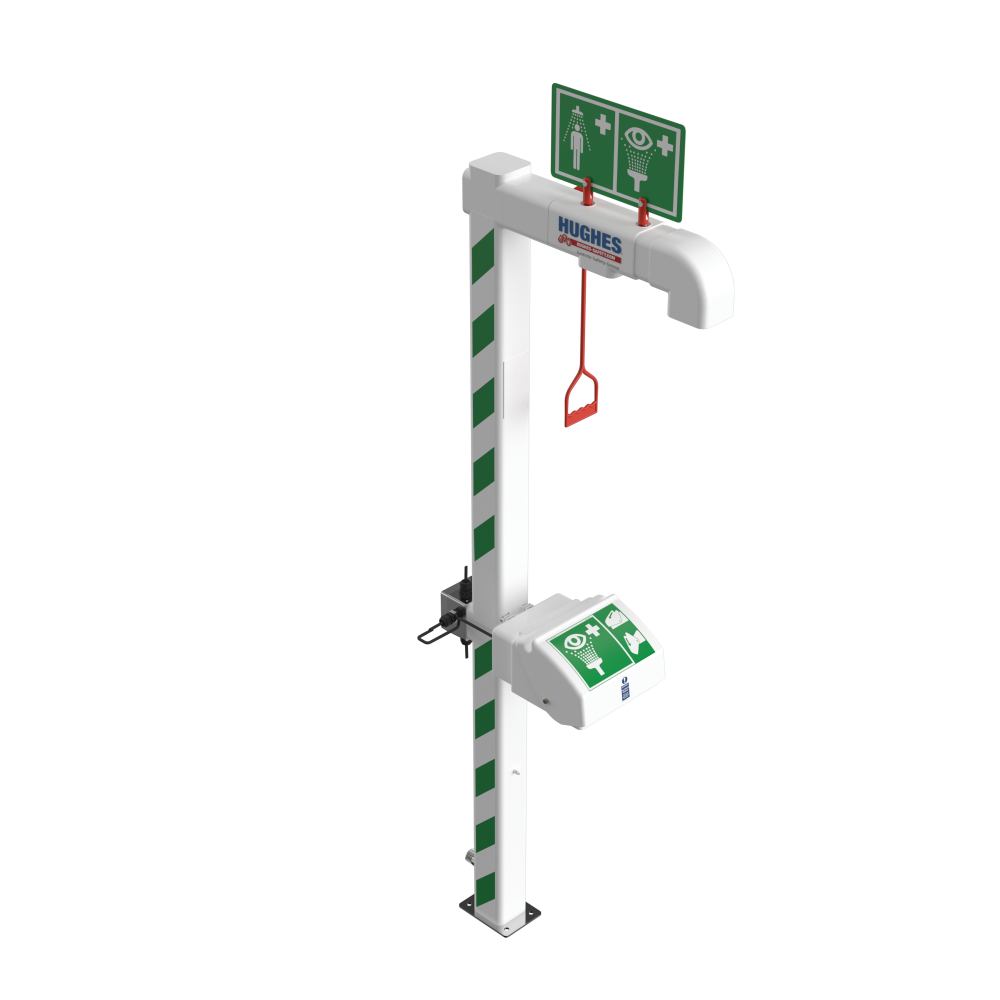

Our mobile range of safety shower solutions are perfect for evolving sites with transient hazards where a fixed unit would be unsuitable.

The mobile units feature a self-contained tank that can be filled at a water source then easily transported to the area with the hazard.

These units can be fitted with a heated and insulated jacket, keeping the water in the tank a constant temperature. Better yet, these jackets are retrofittable to existing units and removeable when the temperature begins to rise again.

Hughes tank showers circumvent problems caused by an unreliable or non-existent water supply by containing the water for the shower within an overhead tank. Our polar tank showers feature an insulated tank and dual thermostat immersion-heater to maintain water temperature within the tank.

The unit features an enclosed cubicle with double-swing doors that shut behind the casualty to protect them from external elements. An additional room heater can also maintain a comfortable temperature within the cubicle.

The 1500L version provides 15 minutes of continuous water flow to comply to international and European safety standards for a thorough decontamination.

Hughes’ showers can be customised with optional fittings specifically for locations susceptible to low temperatures.

Freeze protection valves fit to the water inlet of a plumbed-in shower to reduce the risk of freezing which may render the unit inoperable. These valves work by draining or ‘bleeding’ the water when the temperature approaches freezing, preventing a build-up which could turn to ice and block the inlet or cause damage to the pipework.

If your required product solution is not within our standard range, we can individually engineer, design and manufacture a bespoke product that meets your specific application demands.

When it comes to the cost of keeping workers safe…

“Safety isn’t expensive, it’s priceless.” – Author Unknown

Hughes have extensive expertise in engineering and manufacturing safety showers, spanning over 55 years. For a reliable expert quote on winter-ready safety shower and eye/face wash equipment contact Hughes today.