Enquiry List () (0)

- 19 Feb 2019

Protecting People in the Printing Industry

Due to the fast-paced, deadline-driven nature of the printing industry it can often be easy to overlook the need for health and safety equipment. The UK is the world’s fifth largest producer of printed products, with around 120,000 employees – a large workforce that needs to be protected.

Printing is a diverse industry, covering many processes from screen printing to lamination. As a result, employees are faced with numerous hazardous chemicals including pre-press chemicals, solvents, inks, fountain solutions and adhesives. As such, one of the main adverse health effects reported is dermatitis, caused by irritants coming into contact with the skin.

There are many more serious health issues resulting from the use of chemicals involved in the printing process. For example, chlorinated hydrocarbons in solvents used to clean the press bed and rollers in lithography have the potential to cause problems as severe as liver damage.

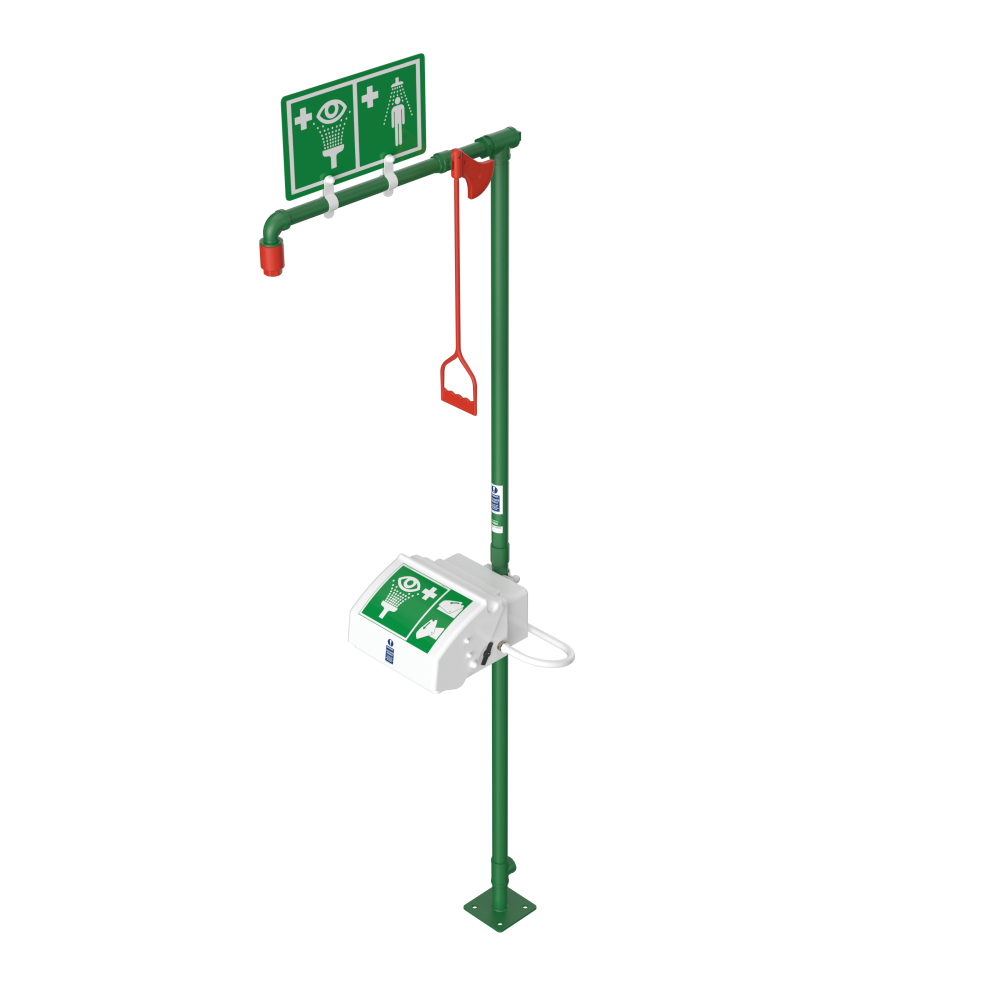

It is imperative that workers who are exposed to these hazardous substances have easy access to safety showers and eye/face wash equipment in the event of a spill to flush these contaminants off their skin, eyes or clothing.

Selecting the right shower

Where a potable water supply is available the Hughes range of unheated indoor emergency safety showers is suitable for all applications not subject to the possibility of freezing or overheating. The scope of this range extends from wall or ceiling mounted units to free-standing models complete with body spray and eye/face wash unit.

Where a potable water supply is available the Hughes range of unheated indoor emergency safety showers is suitable for all applications not subject to the possibility of freezing or overheating. The scope of this range extends from wall or ceiling mounted units to free-standing models complete with body spray and eye/face wash unit.

- Where ammonium dichromate is used as a wet etchant in lithography, it’s important to note that upon contact with the skin this chemical is highly corrosive and requires flushing of the area for at least 15 minutes. The Hughes temperature-controlled emergency safety shower (model shown STD-TC-100KS/11K) is able to maintain the water within a specific temperature range and can also be used to supply heated water to another safety shower nearby.

- Photo-engraving uses acids that can cause irritation or even severe damage to eyes depending on the strength of the chemical. Though in modern printing much of this process takes place within machinery, supplying the equipment with chemicals can still be hazardous. To minimise injury in the event of a spill or splash, in addition to the indoor safety shower range, Hughes also have a wide selection of eye/face wash equipment from pedestal mounted and wall mounted to portable self-contained units.

General considerations for safety showers

When purchasing and placing emergency safety showers, there are several requirements you need to consider, as stipulated by ANSI and EN standards:

- Safety showers and eye/face wash units must be placed with 50 metres of a hazard. Though if the chemical is extremely hazardous, it is recommended that the shower or eye/face wash be placed immediately adjacent to where the process takes place.

- They must be situated in a prominent position, clearly visible, well-lit and free from any obstructions. Remember, a person who needs to use a safety shower or eyewash could have impeded vision.

- Water delivered by the emergency safety equipment should be tepid, between 16-38 C (60-100 F). At temperatures above 38 C (100 F) there is the added danger of scalding and increased absorption of harmful chemicals into the skin. Prolonged exposure to water below 16 C (60 F) increases the risk of thermal shock or hypothermia and prevents the casualty using the shower to decontaminate effectively for the full 15 minutes.

- Emergency safety equipment must be visually inspected and activated weekly along with an annual service to guarantee reliable and effective operation and conformance with the standard.

- Personnel who may be exposed to hazardous materials should be instructed on the safe and proper use of the emergency safety equipment and be advised of its location.

Contact Hughes Safety to learn more. Our professional consultants can advise you on the best solution for your application as well as the regulatory requirements that are relevant to your industry.