Enquiry List () (0)

- 31 May 2023

Whisky Distilleries: Don't Put Worker Safety on The Rocks

Whisky production is an unavoidably time-consuming and expensive process, with some of the world’s most sought-after whiskies taking upwards of half a century to produce. The arduous investment will inevitably prove to be lucrative as fans of the drink can be willing to pay huge margins for older malts. Recently, a bottle of Macallan 1926 60-year-old single malt scotch sold for a record £1.5million. A batch of whisky can sell for a much higher profit the longer it is aged in its barrel due to the smoothness that it develops the longer it infuses with the oak of the barrel. In conjunction with this, roughly 1% of the total amount of whisky within the barrel evaporates each year, meaning that as time goes on there is significantly less of the mixture left. The delicate and prolonged process, from collecting the grain to bottling, means it’s imperative that no external contaminants ruin the batch, which can be a costly error. Such could be the case if the stills, the main drums that carry out the distilling process, are not well and routinely cleaned after each use.

The production process for spirits is not dissimilar to beer production, though the main step separating these is distillation. Distillation is the process used to separate the alcohol from the rest of the liquid wash, which also contains water, a mix of flavourings, as well as some solids and unwanted sulphur compounds. For this, the liquid wash is loaded into a copper still and heated to the boiling point of the alcohol, which is lower than that of water. The alcohol then rises to the top of the still as vapour, travelling along a metal arm (the “gooseneck”) to a cooler where the now separated alcohol will return to liquid form.

While some whiskies may only be distilled once, it is not unusual for others to be double or even triple-distilled to achieve the required flavour notes. Usually, after the initial distillation, the mixture is transferred to a smaller still for any subsequent distilling. Even the size and shape of the still can impact the taste of the whisky, so a thorough clean between uses is mandatory to ensure that a previous batch does not impact the flavours of the next.

While some whiskies may only be distilled once, it is not unusual for others to be double or even triple-distilled to achieve the required flavour notes. Usually, after the initial distillation, the mixture is transferred to a smaller still for any subsequent distilling. Even the size and shape of the still can impact the taste of the whisky, so a thorough clean between uses is mandatory to ensure that a previous batch does not impact the flavours of the next.

Cleaning agents high in acidity, particularly phosphoric acid, are preferred as they are both colourless and odourless. These cleaning agents are usually diluted before use; Star San, for example, recommends a ratio of 1 oz of the cleaning agent for every 5 gallons of water. When diluted, phosphoric acid is generally considered safe and can even be used as a preservative in food and drink. However, if the concentrate spills, it can harm the skin and eyes. Side effects of acidic solutions include dermatitis, pain, eye tearing, and blurred vision. As indicated by the warning labels on such agents, if contacting the clothes, skin, or eyes it is recommended that any contaminated clothing is removed, and the affected area be flushed for 15-20 continuous minutes.

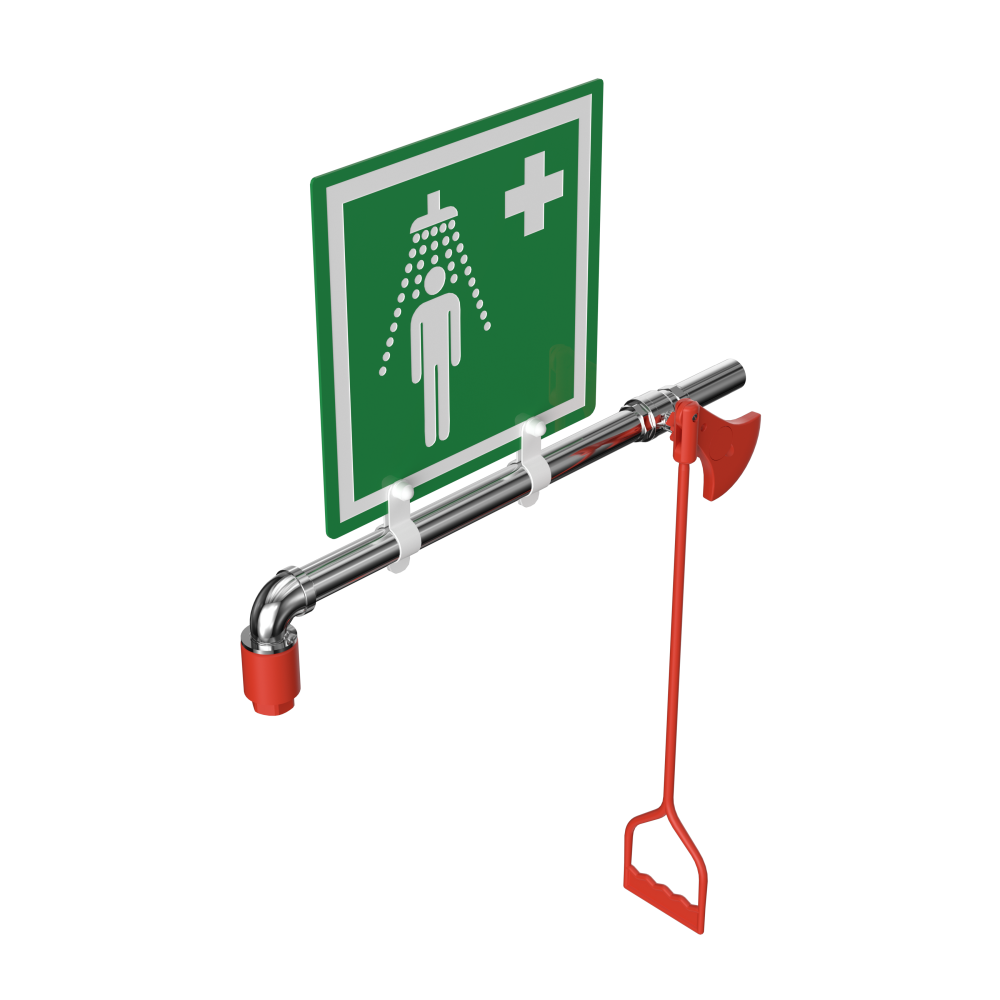

Cleaning products are not the only hazards present in whisky production. Throughout the process, workers are required to transport large volumes of alcohol, in addition to manual handling and extracting samples of the product for testing. Due to the nature of this process, splashes of the excess product are commonplace, but a spill or leak could lead to serious harm. Should a spill occur, it is possible that the handler can be doused in a high concentration of alcohol, presenting a fire hazard. To protect the casualty from harm, they should have access to decontamination facilities to protect them from ignition risks. Indoor drench showers are ideal for distilleries at risk of product and chemical spills.

European and International standards recommend that safety showers and eye washes are placed within 10 seconds’ reach of a potential hazard, on level ground and free from obstruction. Alternatively, safety showers can be positioned next to the storage area of a chemical hazard. Immediate access to flushing facilities prevents the chemical from lingering on the skin which could cause further damage to the casualty.

European and International standards recommend that safety showers and eye washes are placed within 10 seconds’ reach of a potential hazard, on level ground and free from obstruction. Alternatively, safety showers can be positioned next to the storage area of a chemical hazard. Immediate access to flushing facilities prevents the chemical from lingering on the skin which could cause further damage to the casualty.

Hughes has developed a range of safety showers which can be easily situated within a distillery and provide over 15 minutes of water to ensure thorough decontamination. The Mains Fed - Unheated range is perfect for indoor use, with a variety of connection types available. The ring-main and wall-mounted versions are both excellent space-saving options that keep the shower’s footprint to a minimum without compromising worker safety.

Alternatively, Hughes also offer a number of combination safety shower and eye washes. Models like the EXP-18GS/85G can have the safety shower and eye wash activated either simultaneously or independently through different activation methods. This means that if a casualty has suffered from chemical splashes to their eyes, they will not automatically have their body drenched if this is not required. For sites where cleaning equipment is kept outside, Hughes’ range of frost-protected showers ensures functionality even in colder months. The EXP-AH-5GS/45G features an ABS closed bowl eyewash to protect the diffusers from external contaminants while the trace-tape heating, polyethylene jacket, and foam insulation all help to provide protection in freezing conditions.

To further discuss your safety shower and eye wash requirements, submit an enquiry to the Hughes team.