Enquiry List () (0)

- 12 Apr 2024

Where should I position my safety shower and eye/face wash equipment?

In the realm of workplace accidents and chemical spills, every second counts. The rapid response to emergency situations can often be the line between minor inconvenience and severe injury. With regulations such as those set by both international and European standards, the importance of safety equipment positioning cannot be overstated to ensure that anyone affected by a nearby chemical spill can quickly decontaminate to mitigate further harm. In addition to regular workers, site visitors and contractors should also be made familiar with the positioning and use of nearby safety equipment during their induction to ensure the safety of all those on site.

Here are some points to consider when choosing where to position, or find, a safety shower:

Rapid Accessibility

Rapid Accessibility

According to ANSI and EN requirements, a safety shower should be within 10 seconds reach, or 20 metres, of a hazard. This proximity ensures that casualties can quickly access a nearby decontamination station and are exposed to chemical burns for as limited a time as possible, significantly reducing the severity of injuries.

Same Level Placement

Placing the safety shower on the same level as the hazard is paramount. This placement eliminates trip hazards, particularly crucial for visually impaired individuals who may struggle to navigate stairs or ramps in emergency situations.

Clear of Obstructions

The area surrounding the safety shower must be free from any obstructions. This not only ensures quick access to the equipment but also minimises the risk of trip hazards.

Clearly Visibility and Effective Signage

Clearly Visibility and Effective Signage

Visibility is key when it comes to safety showers to ensure new workers or site visitors can easily identify nearby decontamination stations. Regardless of its positioning, the shower must be clearly visible to all workers in the vicinity which can be achieved by additional lighting on the unit. This ensures that workers can familiarise themselves with the equipment available in their area and quickly locate and access the equipment when needed.

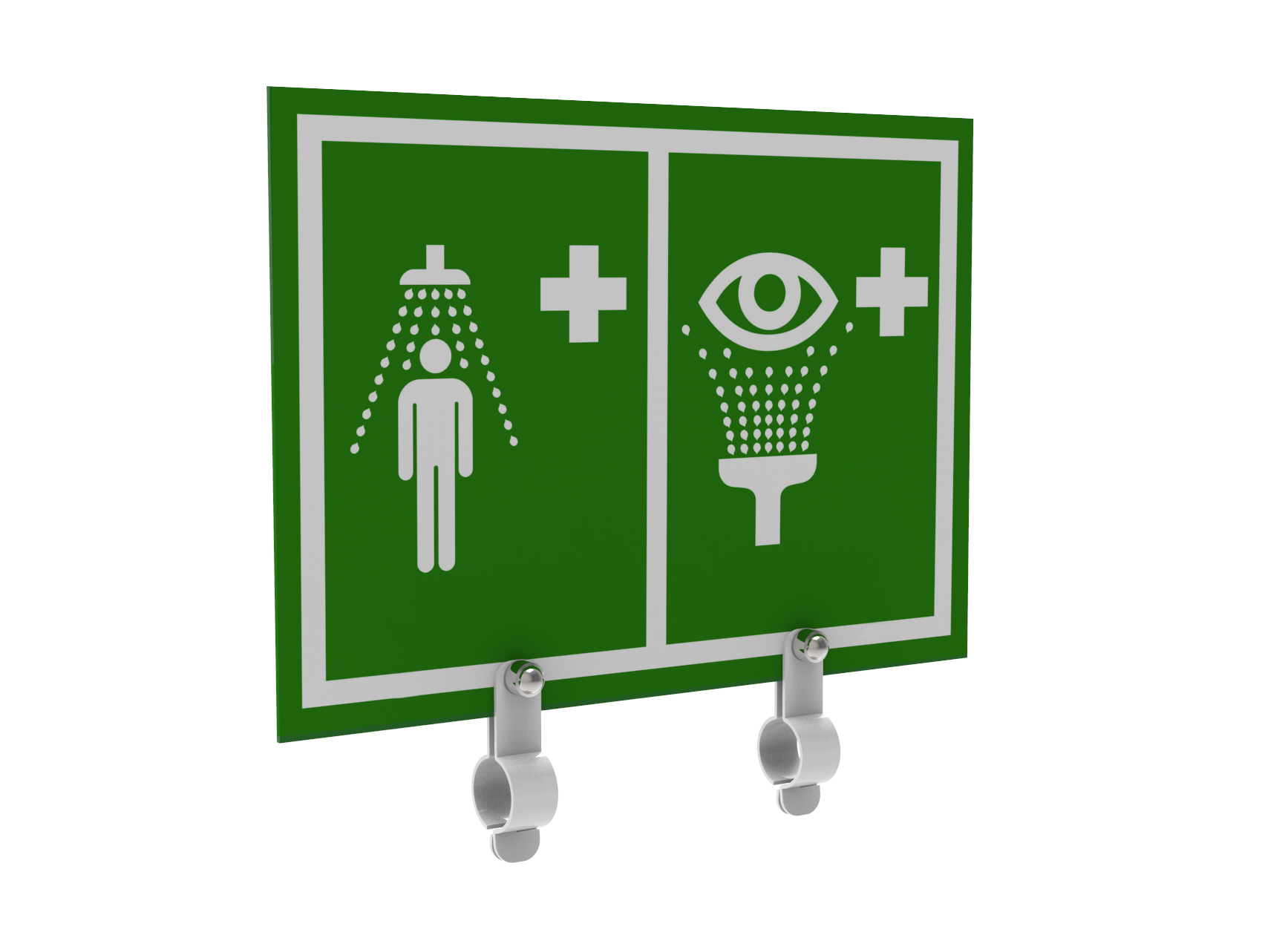

Each safety shower and eye/face wash unit should be accompanied by clear and concise safety signs conforming to BS EN ISO 7010. These signs play a vital role in informing individuals about the purpose of the equipment, whether it's an eye wash station, a safety shower, or a combination unit, preventing hesitation and facilitating prompt action during emergencies.

Training and Awareness

In addition to proper positioning, it's essential to ensure that all workers are informed about the location of decontamination points and trained in proper use of the equipment during emergencies. Any site visitors or working contractors that are new to site should be informed of the location and operation of nearby safety equipment during their site induction. Keeping those on site knowledgeable and up-to-date on safety procedures ensures decontamination is completed quickly and efficiently, preventing prolonged chemical exposure to skin and eyes and even potentially saving lives.

Adhering to ANSI and EN requirements regarding the positioning of safety showers is not just a matter of compliance but a critical aspect of ensuring workplace safety. By following these guidelines and emphasising the importance of rapid accessibility, clear signage, and employee education, organisations can create safer work environments where the risk of chemical-related injuries is significantly reduced.

Hughes Safety Showers are a leading manufacturer of safety shower and eye/face wash equipment with over 55 years of expertise. Our company was born of innovation in site safety and has remained at the forefront of safety equipment engineering ever since. To discuss the safety requirements of your worksite with a member of our expert team, submit an online enquiry.