Enquiry List () (0)

- Jun 26, 2024

What are ANSI requirements for safety showers and eye washes?

The American National Standards Institute are responsible for the internationally recognised safety standard surrounding safety shower and eye/face wash equipment. Compliance to these standards is crucial to ensure your work site supplies the necessary equipment to aid a casualty in the event of a chemical spill and prevent any further harm from being caused.

Positioning

The first step to consider for safety equipment is the location in relation to a hazard. For each hazard, a safety shower and/or eye/face wash station must be positioned within 10 seconds reach of a hazard to comply to standards. The safety equipment should also be on the same level as the hazard and free from obstructions.

Activation

To ensure relief is provided as quickly as possible, standards indicate that safety equipment must activate within 1 second of a valve opening. Nozzles and diffusers should also be protected from external contaminants, as a build-up of debris in either can affect the flow rate or block the system entirely.

To ensure your safety equipment activates when needed, weekly inspections should be carried out in addition to regular servicing. Download Hughes’ weekly activation checklist to know exactly what to look out for when carrying out your inspections.

Flow Rate

Flow Rate

Another vital requirement to comply to either standard is the flow rate. Both standards stipulate that an uninterrupted flow of water is provided for at least 15 minutes to ensure that a casualty can be thoroughly decontaminated. Additionally, a flow rate of 76 liters per minute is sufficient in safety showers to ensure ample water to wash the chemicals from the skin and clothes. In eye/face wash equipment a lesser flow rate of 12 liters per minute is critical to be non-injurious to the eyes and sensitive surrounding skin. An eye/face wash unit providing 12 liters of potable water per minute will comply to both international and European standards.

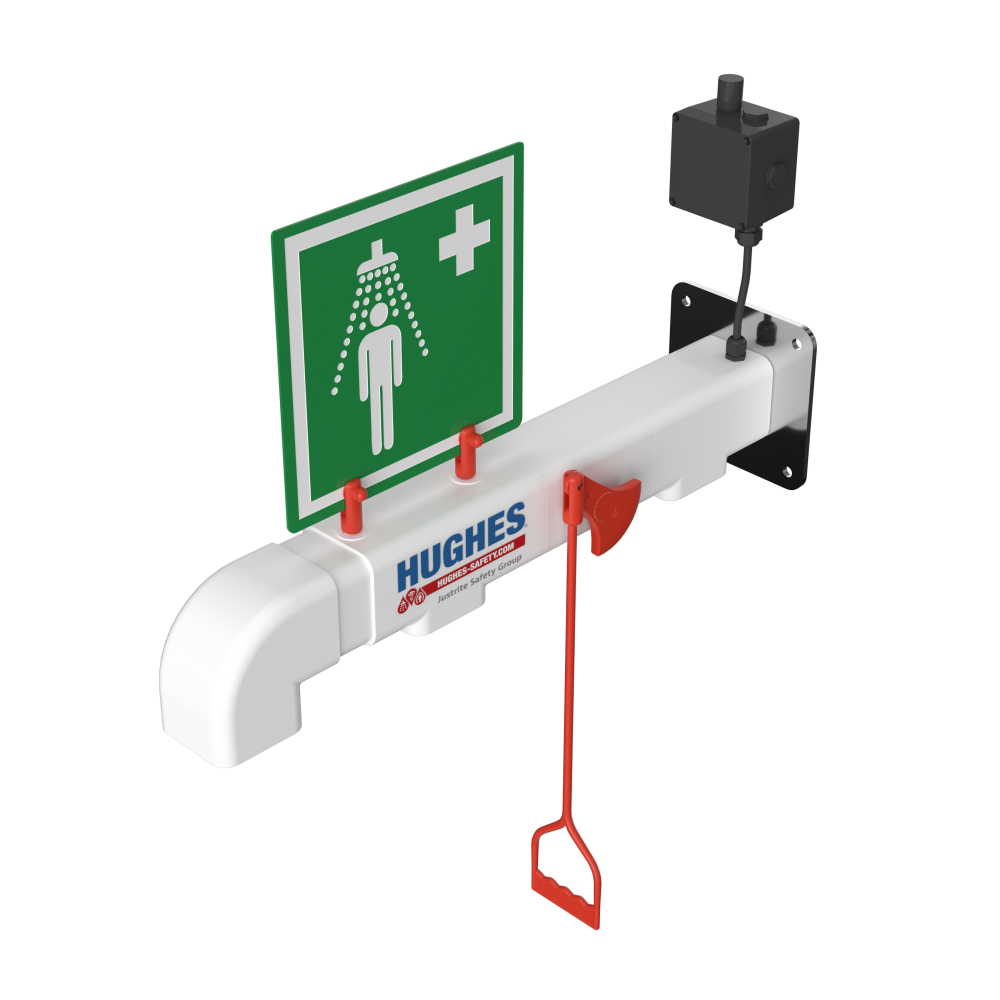

Hughes comprehensive range of indoor combination safety showers provide an all-in-one solution for quickly decontaminating in the event of a chemical splash or spill. Cubicle showers have the added benefit of a confined cubicle which helps to contain the chemicals and contaminated water after use.

Tepid Water

Water from a safety shower or eye/face wash must be in a tepid range for both standards. For ANSI this range is 16-38C (61-100F). This is to keep the casualty comfortable to stop them from withdrawing from the shower before the full 15-minute decontamination and prevent further harm by burns or hypothermia.

For work sites in extremely hot or cold climates this can be challenging, meaning weather appropriate safety equipment is required. Hughes manufacture a line of trace-tape heated and immersion-heated showers for additional layers of protection in cold and freezing climates. Trace-tape heated units provide heating and polyurethane insulation for frost-protection of the pipework. Immersion heated units are effective at tempering safety shower water in temperatures down to -35C (-31F), proving to be the ideal solution for polar climates.

In hot climates, tepid water can be just as challenging to implement. Hughes offer a range of jacketed and insulated models to offer additional layers of protection to the unit, to keep it from heating due to solar radiation. In extremely hot climates our innovative self-draining showers consist of a valve at the base of the unit which drains after use. This prevents water building up in the standpipe and being heated to dangerous temperatures from exposure to the sun.

With over 55 years of manufacturing expertise, Hughes Safety Showers are the leading providers of safety shower and eye/face wash equipment for all industries. For further information on Hughes’ range of safety equipment, from discussing your site’s requirements to pricing and availabilities, fill out our online enquiry form and hear from our team of experts.